High subcooling low suction pressure – In the realm of refrigeration systems, the interplay between high subcooling and low suction pressure holds immense significance. This article delves into the intricacies of this relationship, exploring its impact on system performance, potential causes, troubleshooting techniques, and preventative measures.

By understanding these concepts, refrigeration professionals can optimize system efficiency and ensure reliable operation.

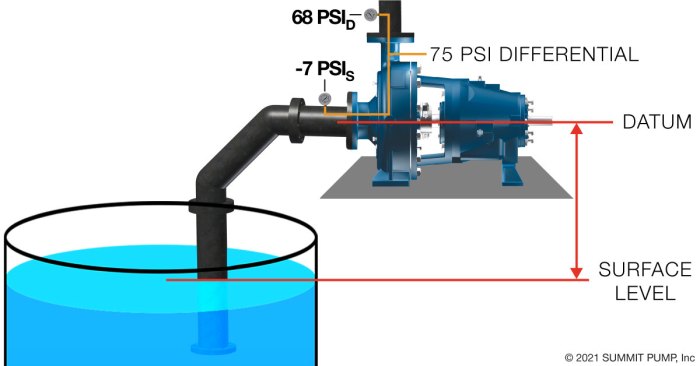

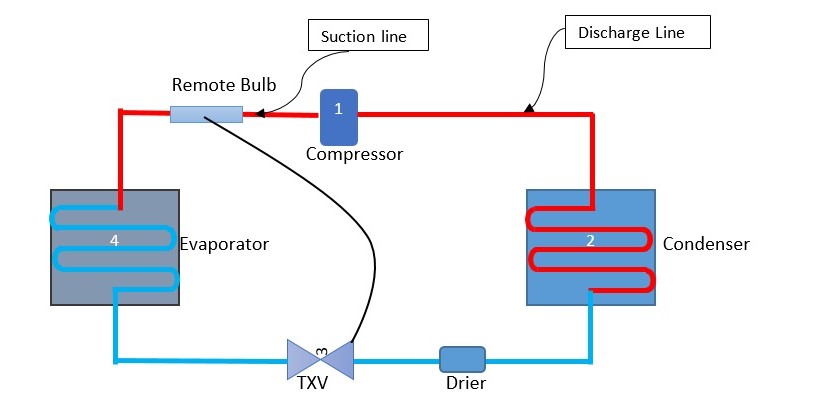

High subcooling, characterized by refrigerant temperatures below its saturation temperature at the evaporator outlet, and low suction pressure, indicating lower-than-optimal pressure at the compressor inlet, can have both beneficial and detrimental effects on refrigeration systems. A thorough understanding of their causes and consequences is crucial for effective system management.

Overview of High Subcooling Low Suction Pressure

In refrigeration systems, subcooling refers to the process of further cooling the liquid refrigerant below its condensation temperature. Suction pressure, on the other hand, is the pressure at the inlet of the compressor. High subcooling and low suction pressure are often desirable in certain refrigeration applications, as they can improve system efficiency and performance.

High subcooling reduces the amount of vapor in the refrigerant entering the compressor, leading to a lower suction pressure. This reduction in suction pressure can result in increased compressor efficiency, as the compressor has to work less to compress the refrigerant vapor.

Additionally, high subcooling can help prevent liquid refrigerant from entering the compressor, which can cause damage to the compressor components. Low suction pressure, in turn, can reduce the load on the compressor, resulting in lower energy consumption and increased system reliability.

Examples of Systems Where High Subcooling and Low Suction Pressure Are Desirable

- Systems with high-temperature loads: In systems where the refrigerant is used to cool high-temperature loads, such as in industrial processes or power plants, high subcooling can help prevent liquid refrigerant from entering the compressor, which is especially important in these applications.

- Systems with long refrigerant lines: In systems with long refrigerant lines, high subcooling can help reduce the pressure drop in the lines, resulting in lower suction pressure at the compressor.

- Systems with variable loads: In systems with variable loads, such as in commercial refrigeration applications, high subcooling can help maintain a stable suction pressure, even when the load varies.

Causes of High Subcooling and Low Suction Pressure

High subcooling and low suction pressure are often symptoms of underlying system issues. Understanding the causes of these conditions is crucial for effective troubleshooting and system optimization.

Causes of High Subcooling

High subcooling can be attributed to several factors:

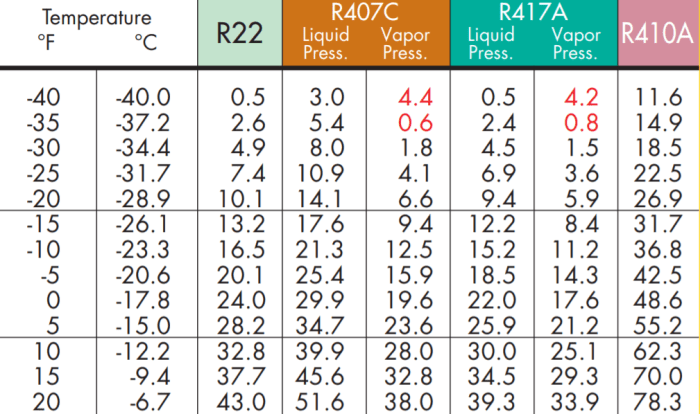

- Overcharged Systems:Excess refrigerant in the system can lead to high subcooling as the refrigerant is unable to fully vaporize in the evaporator.

- Restricted Refrigerant Flow:Blockages in the refrigerant lines, such as clogged filters or expansion devices, can restrict the flow of refrigerant, resulting in high subcooling.

- Faulty Expansion Devices:Malfunctioning expansion devices, such as a stuck-open thermostatic expansion valve, can allow excessive refrigerant flow into the evaporator, leading to high subcooling.

Causes of Low Suction Pressure

Low suction pressure can be caused by various system issues:

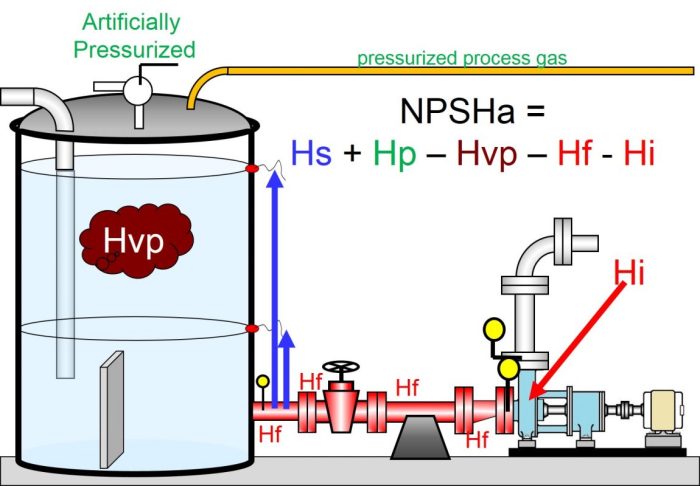

- Leaks:Refrigerant leaks in the system can lead to a decrease in refrigerant charge, resulting in low suction pressure.

- System Blockages:Restrictions in the suction line, such as debris or ice buildup, can obstruct refrigerant flow and cause low suction pressure.

- Compressor Issues:Compressor malfunctions, such as reduced capacity or internal leaks, can lead to a decrease in suction pressure.

Effects of High Subcooling and Low Suction Pressure: High Subcooling Low Suction Pressure

High subcooling and low suction pressure can have several detrimental effects on a refrigeration system. These effects include reduced system capacity, increased compressor work, potential for liquid slugging, decreased evaporator capacity, reduced refrigerant flow, and potential for compressor damage.

High Subcooling

High subcooling reduces the amount of refrigerant that is available for evaporation in the evaporator. This leads to a decrease in the evaporator’s capacity to absorb heat from the refrigerated space. Additionally, high subcooling increases the compressor’s work because it must work harder to compress the refrigerant vapor.

In severe cases, high subcooling can lead to liquid slugging, which can damage the compressor.

Low Suction Pressure

Low suction pressure also has several negative effects on a refrigeration system. Low suction pressure reduces the evaporator’s capacity to absorb heat from the refrigerated space. This is because the lower the suction pressure, the lower the boiling point of the refrigerant.

As a result, the refrigerant will boil at a higher temperature, which reduces its ability to absorb heat. Additionally, low suction pressure can lead to reduced refrigerant flow and potential compressor damage.

Troubleshooting and Solutions

High subcooling and low suction pressure are interconnected issues that can significantly impact a refrigeration system’s performance and efficiency. Troubleshooting and resolving these issues involve a systematic approach to identify and address the underlying causes.

To effectively troubleshoot high subcooling and low suction pressure, it is crucial to understand the system’s operating parameters, refrigerant properties, and component characteristics. The troubleshooting guide below provides a step-by-step approach to help identify and resolve these issues.

Identifying and Resolving High Subcooling

- Inspect the expansion device:Verify that the expansion device is functioning correctly and is properly sized for the system. Adjust the expansion device setting if necessary to reduce subcooling.

- Check for refrigerant leaks:Refrigerant leaks can lead to reduced refrigerant charge and high subcooling. Inspect the system for any leaks and repair them promptly.

- Optimize refrigerant charge:Ensure that the system has the correct refrigerant charge. Overcharging can result in high subcooling, while undercharging can cause low suction pressure.

Addressing Low Suction Pressure, High subcooling low suction pressure

- Inspect for leaks:Leaks in the suction line, evaporator, or compressor can cause low suction pressure. Thoroughly inspect the system for any leaks and repair them.

- Clear blockages:Obstructions in the suction line or evaporator can restrict refrigerant flow and lead to low suction pressure. Remove any blockages to restore proper refrigerant flow.

- Service the compressor:Compressor issues, such as worn valves or reduced capacity, can result in low suction pressure. Service or replace the compressor as needed.

Preventative Measures

Implementing preventative measures is crucial to avoid the occurrence of high subcooling and low suction pressure, ensuring optimal system performance and longevity. These measures encompass proper system design, regular maintenance, and timely refrigerant leak detection.

Monitoring system parameters, including subcooling and suction pressure, is of paramount importance. Regular monitoring allows for the early detection of potential issues, enabling prompt corrective actions to prevent further deterioration and potential system failures.

Proper System Design

- Ensure appropriate refrigerant charge to maintain desired subcooling and suction pressure levels.

- Properly size and select system components, including compressors, condensers, and evaporators, to match the specific application requirements.

- Design systems with adequate heat transfer surfaces in the condenser and evaporator to facilitate efficient heat exchange and prevent excessive subcooling or low suction pressure.

Regular Maintenance

- Perform regular system inspections to identify and address any potential issues, such as refrigerant leaks, dirty coils, or faulty components.

- Clean condenser and evaporator coils periodically to maintain optimal heat transfer and prevent excessive subcooling or low suction pressure.

li>Monitor refrigerant levels regularly and adjust as necessary to maintain the proper charge.

Timely Refrigerant Leak Detection

- Implement a refrigerant leak detection system to promptly identify and locate leaks.

- Regularly inspect system components, such as joints, valves, and fittings, for signs of refrigerant leaks.

- Promptly repair any refrigerant leaks to prevent further loss and maintain optimal system performance.

Frequently Asked Questions

What are the common causes of high subcooling?

Overcharged systems, restricted refrigerant flow, and faulty expansion devices can contribute to high subcooling.

What are the potential consequences of low suction pressure?

Low suction pressure can lead to decreased evaporator capacity, reduced refrigerant flow, and potential compressor damage.

How can I troubleshoot high subcooling and low suction pressure?

A troubleshooting guide is provided in the article, including steps to identify and address the underlying causes.

What are some preventative measures to avoid high subcooling and low suction pressure?

Proper system design, regular maintenance, and timely refrigerant leak detection are essential preventative measures.